- Introduction:

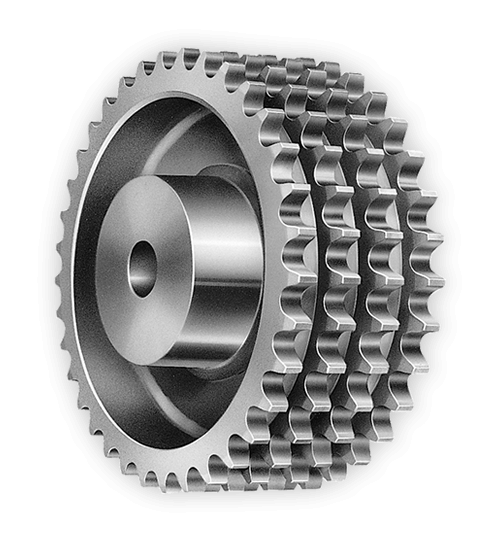

We are able to provide our esteemed clients with a broad choice of Chain Sprocket thanks to our years of industrial experience. We are the top manufacturers of Chain Sprockets in Ahmedabad,This sprocket is made by our subject-matter experts using premium mild steel and is frequently used to convey rotary motion between two shafts. Additionally, we verify that this sprocket is defect-free before it is finally dispatched.

- Chain sprockets:

Chain sprockets play a crucial role in the efficient and reliable operation of many types of machinery, from bicycles and motorcycles to industrial equipment and conveyor systems. Choosing the right chain sprocket for your application is essential for achieving optimal performance and maximizing the lifespan of the equipment.

One of the most important factors to consider when selecting a chain sprocket is the pitch, or the distance between the centers of two adjacent chain pins. The pitch of the chain and sprocket must match in order for them to fit together properly and transfer power efficiently. Choosing the wrong pitch can result in excessive wear, noise, and reduced performance.

Another important factor is the tooth count, which refers to the number of teeth on the sprocket. The tooth count affects the speed and torque of the machine, with fewer teeth resulting in higher speed and lower torque, and more teeth providing lower speed and higher torque. It is important to choose a tooth count that matches the requirements of your application.

The material of the sprocket is also a critical consideration. Chain sprockets are typically made from steel or aluminum, with each material offering its own advantages and disadvantages. Steel sprockets are durable and can withstand heavy loads, but they are heavier and may require more maintenance. Aluminum sprockets are lighter and require less maintenance, but they may not be as strong and can wear more quickly.

Finally, the shape and configuration of the teeth on the sprocket can also impact performance. Different tooth shapes, such as round, square, or pointed, can affect the engagement of the chain and sprocket, as well as the noise and vibration of the system. Custom sprockets with unique tooth shapes or spacing can also be designed to optimize performance for specific applications.

In summary, choosing the right chain sprocket is essential for achieving optimal performance and longevity in your machinery. Consider factors such as pitch, tooth count, material, and tooth shape when selecting a sprocket for your application, and be sure to follow proper maintenance procedures to ensure reliable operation over time.

No comments:

Post a Comment